Intensification Strategies Start With a Focus on Process Development

Optimized Scalable Process for Shorter Time to Market

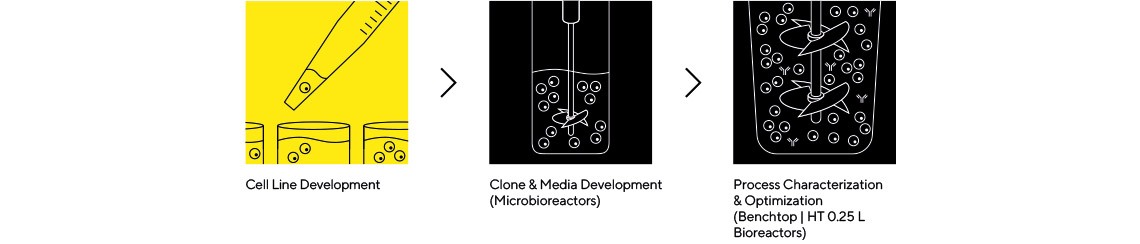

Efficient process development (PD) including a high-titer cell line, clone selection and optimization, and process characterization is critical to develop a scalable upstream process. Now, with technology scalable to fit different intensified process types, PD also enables opportunities to optimize.

Sartorius offers PD solutions for high productivity, flexible upstream intensification processes and increased speed to IND.

Intensify process development at an early stage with state-of-the-art high throughput Ambr® systems and analytical tools

Cell line development and media optimization, cell banking and state of the art analytical tools save weeks of development and investment

Faster scalable process development and optimization with Ambr® 250 perfusion high throughput system speeds the development time

Optimized scalable process from PD to manufacturing for any intensified scenario

PI Process Compatibility Starts Here

Cell Line Development (CLD) includes gene cloning, cell line selection and characterization, media selection and Master Cell and Working Cell banking. Many regard the selection of the appropriate production clone as the most critical step in CLD. If the PD team starts with one clone and then decides to switch to another, it would require major process changes . These changes would bring both significant delays and additional costs.

This is why development and characterization of the cell line for identity, purity and stability are crucial. Sartorius is a reliable partner for these critical steps, offering a Cell Line Development Service, a high-titer cell line with CellcaCHO Expression Platform, and perfusion enabled media.

The Intensification Potential with CellcaCHO

The CellcaCHO Expression Platform is a scalable cell line and fed-batch process development system. It delivers stable research clones from DNA to research cell bank in 14 weeks and a fully characterized master cell bank in 10 months.

The CellcaCHO supports the potential of optimization:

- Combine with N-1 perfusion to more than double titer with 30-40% fewer culture days in the production bioreactor, resulting in up to 2x productivity

- Use in concentrated fed-batch to enable a double-digit titer resulting in up to 4x productivity

- Pair with dynamic perfusion to achieve a 5x increase in productivity

Chemically Defined, Optimized and Highly Productive

The 4Cell® XtraCHO-Media system is chemically defined and optimized for CHO DG44 cell lines:

- Contains CHO media and feeds, optimized for protein manufacturing

- Supports rapid growth to high densities and high cell growth rates compared to standard-serum supplemented media

- All the critical parameters (e.g., viability, titer and lactate) remain consistent while cultivating the cells in bioreactors with various volumes

- Processes can be easily transferred and scaled-up to bioreactors up to 2000 L, saving up to 3 months for scalability studies

The 4Cell® XtraCHO-Media system is cost-efficient, compliant with regulatory guidelines, and provides reliable batch-to-batch consistency.

Intensify to Meet Current and Future Demands

Optimization for High Productivity

Cell culture media optimization is a crucial point of focus when exploring perfusion processes to achieve higher productivity. The medium should support rapid growth to high densities, achieve high cell growth rates with maximum viable cell concentration and provide batch-to-batch consistency.

Process Development Services for Perfusion Process Optimization

Many cell lines were identified in a standard fed-batch process performed in Ambr® 15 microbioreactors. These cell lines show high intensification potential, but the best clone from standard fed-batch selection might not be the best in perfusion.

Mimicking the perfusion process for clone selection will not only save time, it can also enable a three-fold increase in productivity. Sartorius‘ Process Development Service makes this possible by offering a combined solution that includes cell line, media, process development and the technology to deliver optimal results.

Rely on Ambr® 15 to Deliver the Data Needed for Intensification

The Ambr® 15 is the smallest single-use bioreactor on the market with system automation and parallel operation, and can be a starting point for process intensification:

- Identify suitable clones, media and feeds to achieve great performance in perfusion mode

- Mimic perfusion process to produce reliable and relatable data for intensified processes

- Reduce cost-per-experiment by saving substantial amounts on facility space, capital, labor, media and consumables

An Easier Path to DOE

MODDE® is an easy-to-use solution for Design of Experiments (DOE). It offers design space functionality, multiple automated workflows, and improved process understanding through visualization and graph interaction. With an efficient DOE approach to problem-solving, you can:

- Significantly reduce experimental costs

- De-risk projects and increase success rates

- Make the most of valuable samples, raw materials and human resources

- Accelerate progress and time-to-market while keeping within budget

- Achieve quality goals and satisfy Quality by Design requirements

iQue3 for Actionable Results from Smaller Samples in Record Time

iQue3 is an advanced flow cytometry platform for high throughput clone screening.

- Rapid microvolume sampling provides the fastest sample acquisition in the industry

- 96-well plates processed in as few as five minutes

- 384-well plates in 15-20 minutes

- Requires the smallest assay volumes and sample volumes – as little as a 1 mL – saving reagents and conserving precious cells

- Key applications for iQue3 with process intensification are clone ranking and selection of production clones with rapid and simultaneous evaluation of IgG titer, specific productivity, and cell health

Intensify to Meet Current and Future Demands

Process Characterization for Establishing Perfusion-Based Processes

Characterizing an established perfusion-based process in scale-down models helps identify the economy of the process while mimicking the performance of large-scale bioreactors. Process parameters such as cell density and viability, titer and lactate level must be monitored in real-time to get the most benefit from the data.

Sartorius offers single-use and scalable technology solutions to supports perfusion-based process development.

Biostat® B-DCU Benchtop Bioreactor

The Biostat® B-DCU benchtop bioreactor with advanced PAT and MFCS perfusion recipes can be used from screening to characterization of intensified processes.

- Offers unparalleled flexibility through universality

- Has working volumes from 250 mL to 10 L

- Includes aeration and feeding strategies with sensor technologies to mimic commercial-scale bioreactors

- The two mass flow controllers allow a flow range from 1 mL to 20 L per minute with a single system

- Easy upgrades through additional supply towers

A Fully Integrated Solution for Perfusion at PD Scale

Ambr® 250 HT perfusion supports the rapid development of scalable perfusion processes:

- Up to 24 x 100-250 mL single-use perfusion bioreactors operating in parallel

- Includes a fully automated liquid handling platform

- Reduces systems hands-on time by 50%

- Requires 13% less media than benchtop bioreactors for lower experiment costs

Only Sartorius offers a fully integrated solution for perfusion at the PD scale. Processes developed in Ambr® systems can be easily scaled up to STR 2000 L as well as RM Perfusion for seed train flexibility.

Octet Systems for Functional Characterization and Protein Quantitation

Octet is a low maintenance, label-free biomolecular interactions analysis platform. It monitors binding of proteins from solution to a biosensor surface in real time. Using Octet during process characterization effectively:

- Reduces experiment time: 96 samples in 20 minutes, 384 samples in 70 minutes

- Delivers 20x faster than traditional ELISA and HPLC (IgG titer)

- Operates 2x faster than traditional SPR (method development)

- Increases capacity for QC samples testing

- Only requires 10% the hands-on time of traditional ELISA

Key applications for process intensification are functional characterization and protein quantification, as well as glycan screening and contaminant testing. Octet can also be used for residual host cell protein detection.