Disposables & Wearables – Promoting the Success of Healthcare

From Raw Materials to Finished Products

Designed for comfort, safety and robustness, produced in large numbers with maximum production speed and cost efficiency: the spectrum of single-use medical products is tremendous. It ranges from Personal Protective Equipment (PPE), fixation accessories, bandages, needles, syringes up to dialysis filters or wearables like cardio-watches, sensors, hearing aids or ECG and blood pressure monitors which provide important data to monitor patient health and understand treatment effects.

Stringent quality control (QC) is a key factor for successful commercialization of wearables and disposables. It offers the potential to de-risk projects, increase success rates, significantly reduce costs and accelerate time-to-market. Deviations or fluctuations can be detected in time to avoid higher production costs, downtimes or product recalls.

Let Sartorius help you reach full QC potential!

A Deeper Look into the Process Steps for Medical Device QC

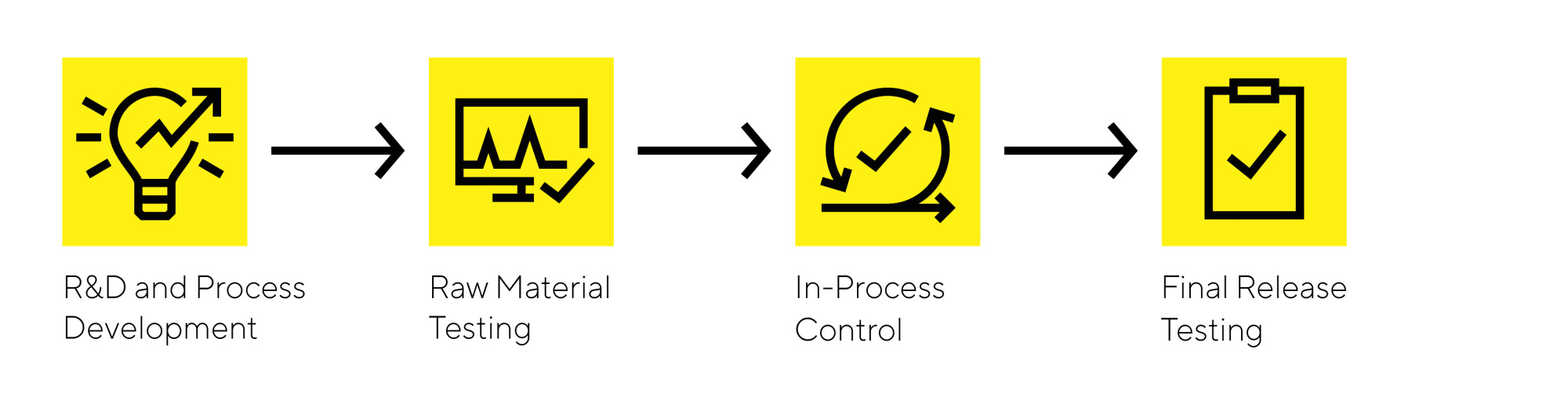

Medical Device Manufacturing Workflow

R&D and Process Development

Continuous improvement is vital for consumer comfort, better efficacy, aesthetic appeal, and optimized production speed. It all starts in the design and development phase.

Discover R&D and Process Development solutions for your application:

- Density Check of Solid Material & Liquids

- Chemical Characterization - Biocompatibility

- Cytotoxicity - Biocompatibility

- Data Analytics

Raw Material Testing

The quality of the final product depends on the quality of the raw materials. To ensure device performance and patient safety, your raw materials must be stable and safe for use and meet stringent ISO, USP, EP, ChP, JP, and ARTG testing standards.

Discover the Raw Material Testing solutions for your application:

- Density Check of Solid Material & Liquids

- Moisture Determination of Raw Material

- Particulate Matter Analysis

- Chemical Characterization - Biocompatibility

- Microbial Testing: Water & Bioburden Testing

In-Process Control

In-process quality control tests are performed at regular intervals to verify product quality and specifications at every stage of production.

Evaluate the correct quantity of adhesive on a plaster or check the moisture absorption of an adhesive placed on a wearable. Test ultrapure dialysis fluid to comply with maximum allowable levels for bacteria and endotoxins.

Discover the In-Process Control solution for your application:

- Check Coatings – Application of Correct Amounts

- Moisture Determination

- Particulate Matter Analysis

- Continuous Microbial Air Monitoring

- Rinsing & Sterile Preparation

- Data Analytics

- Counting with Reference Weight

Final Release Testing

Every lot requires testing to demonstrate compliance to regulatory guidelines. Chemical characterization - conforming to controlled tolerances - is necessary to avoid skin irritation and prevent allergies.

Discover the Final Release Testing solutions for your application:

- Check Coatings Application

- Error-Proof Packaging

- Density Check of Solid Material & Liquids

- Moisture Determination of Packaging Material

- Microbial Testing: Bioburden & Sterility

- Chemical Characterization - Biocompatibility

Featured Products

Microsart® @filter

Membrane filtration solutions for standard microbial enumeration protocols facilitate accurate detection of potentially pathogenic or spoilage microorganisms.

Frequently Asked Questions

- Isolate your sample from the surrounding environment

- Stir sample if needed to achieve homogeneity

- Accuracy and repeatability can often be improved by sandwiching between two filter pads

The total solid content is defined as the mass of polymer per volume of latex, given in percent per weight (i.e. volume of particle phase to total volume of dispersion). A finished medical glove has a TSC of 100% since the substrate should not contain appreciable or significant amounts of water.

Moisture analyzers LMA200 can deliver TSC results within minutes. LMA200 helps optimize production of gloves and saves raw materials by applying the exact amount of latex your product needs.